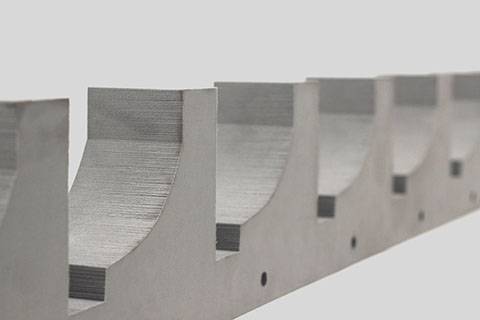

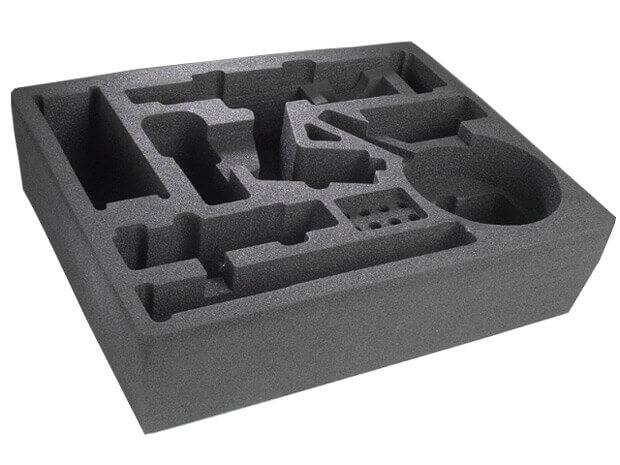

Protective FOAM Dunnage

R&R Packaging Solutions offers custom foam dunnage designed to be used in steel racks, bulk containers, and or totes. R&R uses many different types of foam material, for example, cross-linked polyethylene(XLPE), expanded Polypropylene, and expanded polyethylene. The foam can be manufactured by using a water-jet cutting process, die-cut, and or an aluminum cast tool. These different types of foam provide excellent surface part protection, cushion during transit, and helps eliminate vibration. All of these foam materials are available in different density weights depending on particular protection need. They also come in a few different colors.

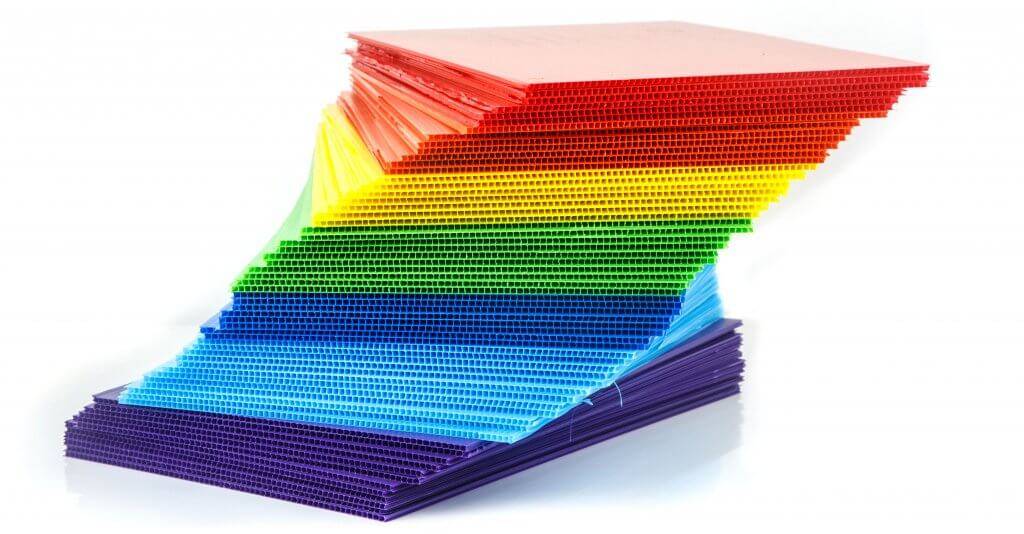

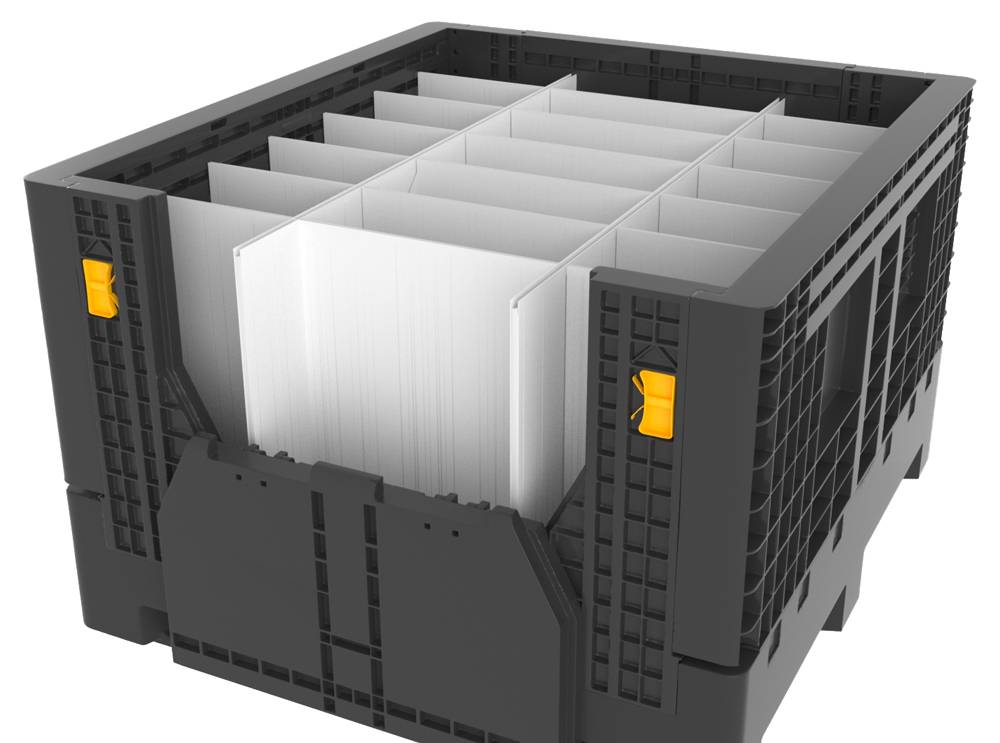

Protective Plastic Dividers

R&R Packaging Solutions plastic dividers are made from polypropylene and or polyethylene which outperforms and outlasts similar dividers made of traditional cardboard. These dividers come in many different thicknesses, 3mm, 4mm, 5mm, 6mm, and 8mm. The most common dividers have a fluted structural substrate. However, if more strength and durability are required, a unique oscillating fluted structural substate is used. These structural substrates are available plain or laminated A-class surface protection material, like brushed nylon, soft polyspun, and or crosslink foam. The dividers are die-cut in all different shapes and sizes and can be installed into totes, bulk containers, and or steel racks. R&R Packaging Solutions also offers dividers using a solid structural substrate for heavily weighted parts.

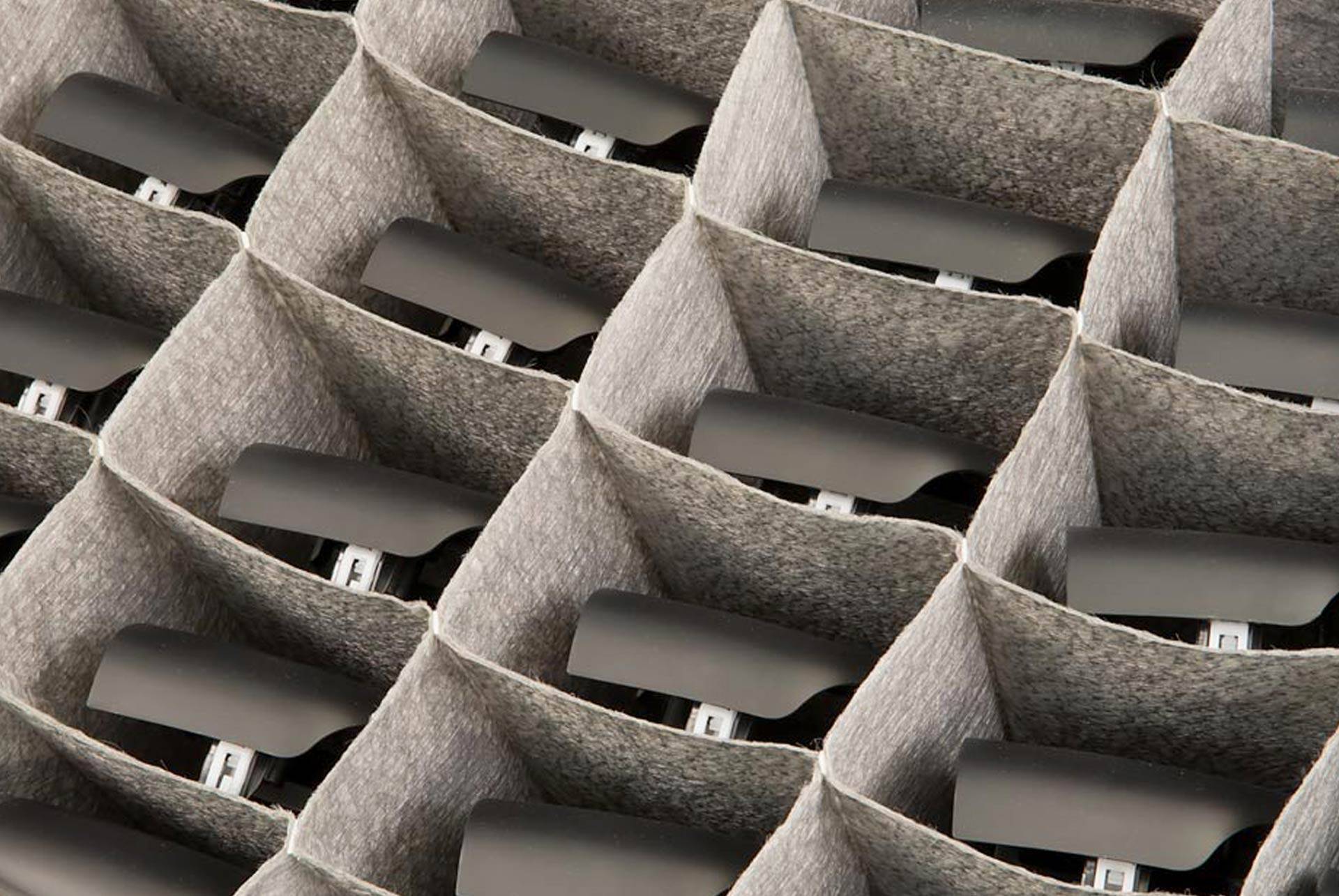

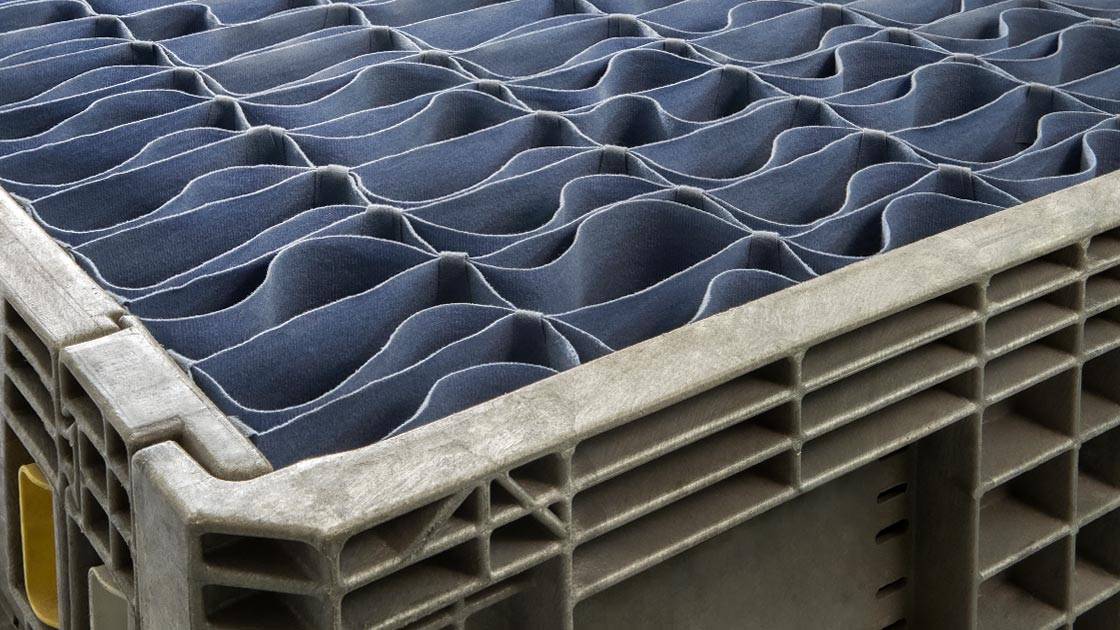

Protective Fabric Dividers

R&R Packaging Solutions offers sewn and welded fabric dividers. These textile designs allow for increased part nesting achieving overall higher pack/trailer density still maintaining great A-class surface protection. Increasing pack/trailer densities allow for maximizing freight utilization reducing total freight cost optimizing transit cycle and supply chain. R&R Packaging Solutions only uses proven durable textile fabrics to provide longevity. The fabric pouches can be designed to easily adapt into existing steel rack frames and or bulk containers/totes. The fabric sewn dividers do not require any tooling.

Protective Fabric (Welded) Dividers

R&R Packaging Solutions offers unique welded fabric dividers. These textile designs allow for increased part nesting achieving overall higher pack/trailer density still maintaining great A-class surface protection. Increasing pack/trailer densities allow for maximizing freight utilization reducing total freight cost optimizing transit cycle and supply chain. R&R Packaging Solutions only uses proven durable textile fabrics to provide longevity. The fabric dividers can be designed to easily adapt to existing bulk containers and totes. The fabric welded dividers do not require any tooling and can be manufactured in half the lead time of sewing dividers especially with high-density packs. We have the ability to match your returnable fabric with a paper expendable divider as shown in the picture below.

Fabric Slide Packs

R&R Packaging Solutions offers custom innovative fabric slide packs which are ergonomically friendly for the operator to load and unload. The slide packs are designed from a variety of fabric materials where the final sewn pouches hang from two fixed rods mounted inside a bulk box. The slide packs are also designed so you do not have to walk around the container. They are accessible from one side by sliding the hanging fabric pouches back and forth. The slide packs can be designed with multiple layers eliminating the need to remove layers from the container where they can get damaged and or lost. These slide packs eliminate the need for extra line space for stacking empty dunnage trays.